The Role of 3D Printing in Streamlining Modern Manufacturing Solutions

- i-SOLIDS

- Jul 17, 2024

- 3 min read

In an era where innovation and efficiency are at the forefront of industrial progress, 3D printing emerges as a revolutionary force in modern manufacturing solutions. This transformative technology not only promises to reshape how products are designed and produced but also holds the potential to significantly reduce costs, enhance customization, and streamline production processes across various industries.

Understanding 3D Printing in the Manufacturing Industry

3D printing, or additive manufacturing, stands as a beacon of change in the manufacturing world, offering a layer-by-layer approach to production that contrasts sharply with traditional subtractive manufacturing methods. By enabling the creation of complex and lightweight structures without the need for molds or cutting tools, 3D printing technology ushers in a new era of design freedom and innovation.

The pertinence of 3D printing in manufacturing lies not only in its ability to turn digital blueprints into tangible objects but also in its capacity to streamline production processes. This has led to its adoption across various sectors, ranging from aerospace to healthcare, where customized parts are in high demand.

Revolutionizing Prototyping and Production Processes

3D printing has radically transformed the prototyping phase, significantly reducing the time and expense involved in product development. Designers and engineers can now iterate rapidly, making adjustments on the fly, which is crucial for innovation and speed-to-market in today's competitive landscape.

Moreover, the shift towards using 3D printing for end-use productions is increasingly becoming a reality. This shift is driven by advancements in 3D printing materials and technologies, making it possible to produce items that meet or even surpass the quality and durability of traditionally manufactured products.

Cost Reduction and Efficiency Enhancement

One of the most compelling arguments for the adoption of 3D printing within the manufacturing industry is its potential for cost reduction. By minimizing material waste and reducing the need for inventory, 3D printing helps companies achieve better resource efficiency.

Furthermore, 3D printing allows for the production of components on demand, which can significantly lower storage and inventory costs, providing a streamlined approach to supply chain management.

Customization and Flexibility in Manufacturing

The flexibility of 3D printing introduces unparalleled levels of customization to manufacturing, enabling the production of components tailored to specific requirements. This aspect is particularly beneficial in industries such as healthcare, where personalized implants and prosthetic devices can greatly improve patient outcomes.

The Environmental Impact of 3D Printing

3D printing's ability to reduce waste and energy consumption presents a more environmentally friendly option compared to conventional manufacturing methods. The technology's additive nature means that materials are only used where needed, minimizing excess and potentially reducing the carbon footprint of manufacturing operations.

Case Studies: Success Stories and Lessons Learned

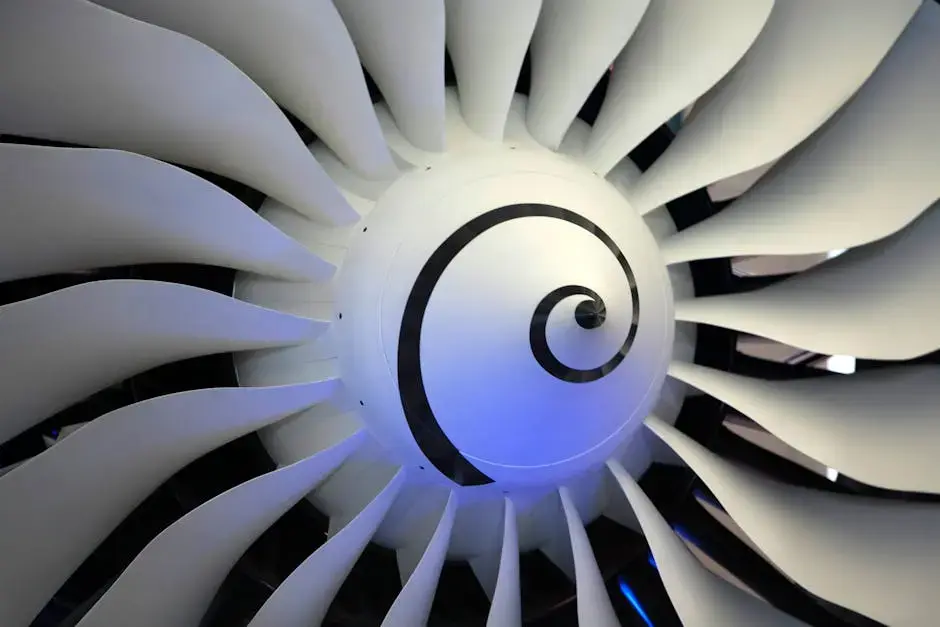

Across industries, there are numerous success stories of companies leveraging 3D printing to innovate and improve efficiency. For instance, in aerospace, companies like Boeing have incorporated 3D-printed parts into their aircrafts, resulting in lighter, more fuel-efficient planes.

The Future of 3D Printing in Manufacturing Solutions

The promising trajectory of 3D printing suggests that it will continue to evolve, with ongoing research and development focused on expanding the range of materials and improving the speed and quality of prints. As such, the future of manufacturing will likely see an even greater integration of 3D printing technology, further revolutionizing the industry and paving the way for innovative manufacturing solutions.

Embracing the Future of Manufacturing

As we delve into the intricacies of 3D printing technology and its application in modern manufacturing, it's clear that this innovation is more than just a fleeting trend. It represents a significant leap toward more efficient, sustainable, and customizable manufacturing solutions. By embracing 3D printing, industries can look forward to a future where production constraints are minimized, creative possibilities are expanded, and environmental impacts are significantly reduced.